Luoyang QIBR Bearing company was established in 2002, which is a high-quality bearing manufacturing company that specializes in production, design, research and development. With over 22 years of experience in power transmission, the company possesses advanced technological research and development capabilities. Its product range mainly consists of three types: high-speed precision angular contact ball bearings, thin section ball bearings, and high-precision, low-noise deep groove ball bearings. These products are widely used in various industries including automotive transmission systems, high-precision CNC machinery, Ultra-high speed motorized spindle device, wind and solar energy equipment, and diversified industrial sectors.

QIBR has established a municipal-level technology center and a state-level specialized bearing engineering technology research and development center to develop new products and enhance the functionality of bearing designs. The company owns three major experimental centers for material analysis, physico-chemical experiments, and precision measurement. It strictly adheres to the German TUV ISO9001:2015 and ISO14001:2015 management systems, employs online inspection and SPC process control systems to achieve full monitoring and tracking of product processes. Our core technologies and key products ensure its leading position in the international market.

QIBR is dedicated to producing high-precision, high-quality bearings and has gradually become one of the comprehensive manufacturers in the China bearing industry, integrating production, sales, warehousing, and distribution.

1. Why Choose QIBR Bearings?

- QIBR owns a professional team of technical engineers who provide a range of services including technical consultation, fault detection, and fault analysis.

- OEM/ODM is available: We offer extensive OEM/ODM service, catering to the customization needs of world’s top enterprises. Our professional OEM/ODM team has rich experience in product design, production, and delivery.

Learn more about OEM-related case

- A leading Chinese quadcopter drone manufacturer

- A prominent Chinese new energy vehicle manufacturer

- A globally recognized elevator manufacturer

- A world-renowned machine tool manufacturer

- A globally acclaimed robotic arm manufacturer.

- Warranty: QIBR offers a one-year warranty period from the date of delivery.

- With over 20 years of experience in bearing manufacturing and sales, QIBR has established two wholly-owned factories in China equipped with over 20 production lines. This ensures quality assurance and high levels of reliability.

- From conception to bearing design solutions, QIBR assists customers every step of the way.

2. QIBR Can Undertake Research & Development Projects in:

- Super-high-speed ball bearings (inner diameter above 6mm, outer diameter below 360mm, speed factor less than 4 million)

- High temperature & high-speed bearing (Inner diameter above 6mm, outer diameter below 200mm, operating temperature below 470°C, speed factor less than 4 million)

- Thin section ball bearings: (width above 3.969mm, outer diameter below 300mm)

- Special bearings with functional coatings

- Special bearings for difficult-to-process materials

Company

Profile

QIBR is committed to

establishing long-term cooperative relationships with customers, providing innovative products, and cultivating professional employees.

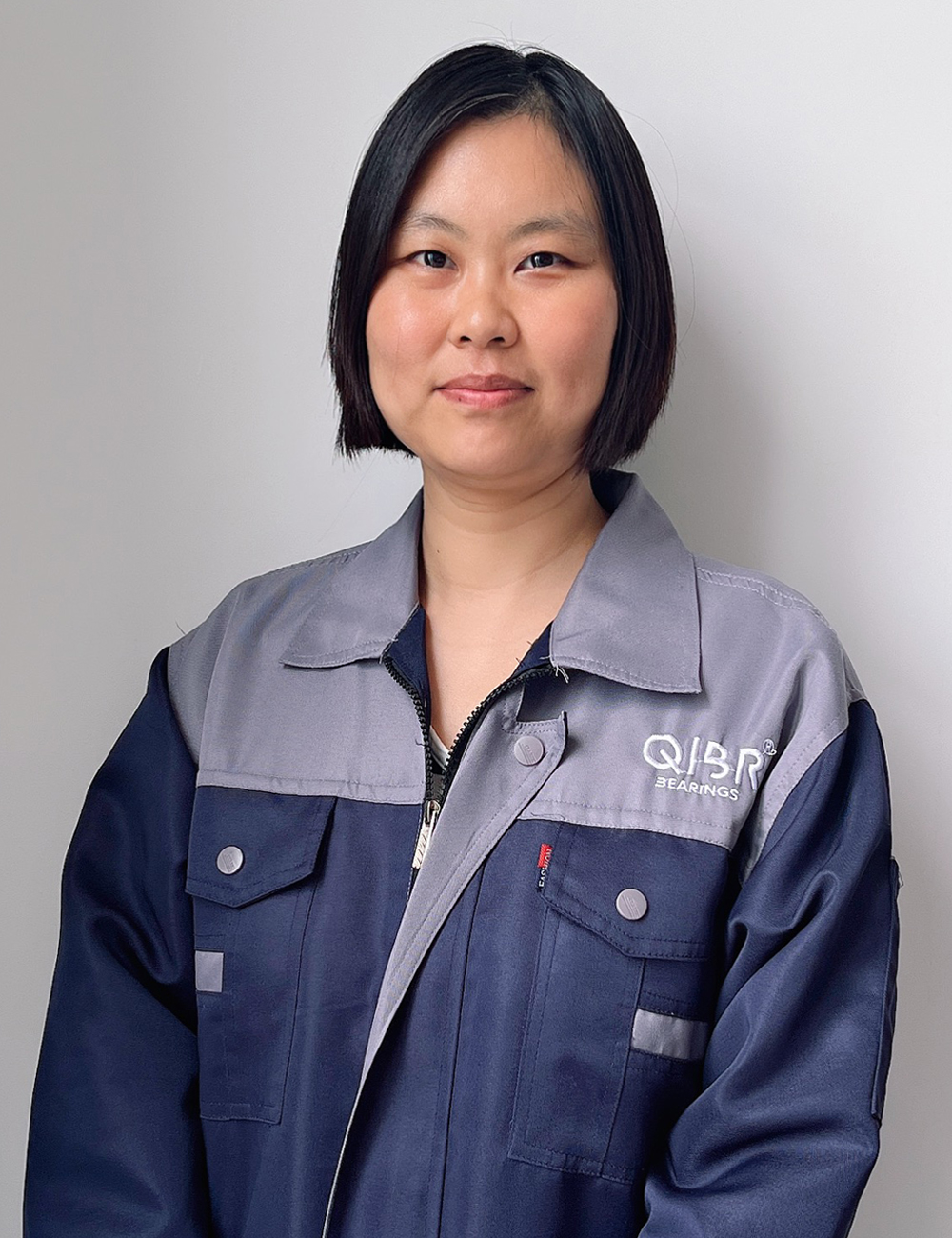

Liu Bing

We established a bearing sales company in Luoyang, which is one of China's famous heavy industry cities and one of the most important bearing production bases in China. It has more than 5,000 years of civilized history, more than 4,000 years of urban history, and more than 1,500 years of capital history.

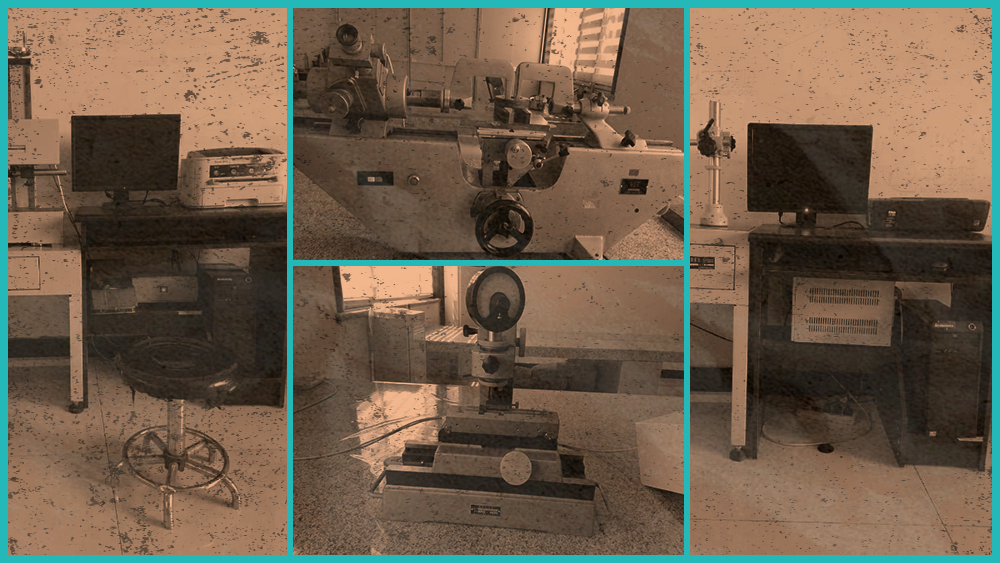

In order to ensure the quality control of the products sold, we purchased many measuring instruments and established a laboratory to conduct 100% quality control of the precision bearings sold by our company.

Since the company's product sales business has been extended to the sector of automotive bearings, our company's turnover has increased by 200% in both the domestic market and external markets.

The QIBR brand was registered in China, the United States, the European Union, Turkey and other countries, which fully reflected the brand strategy.

The company acquired 9,372 square meters of land through bidding and auction, and the Luoyang factory passed ISO9001:2008 quality system certification.

Due to the increasing business volume, in order to further ensure product quality, QIBR began construction of the QIBR factory, covering an area of 6,000 square meters. The effort marks a key moment in the company's expansion strategy and its commitment to increasing production capacity and promoting regional economic growth. Once completed, the plant is expected to significantly increase QIBR's production capacity, allowing the company to meet the changing needs of its global customers while maintaining strict quality standards.

Commissioning in the production workshop. The commissioning of the production workshop heralds QIBR's entry into a new era of excellence and innovation, propelling the company to greater success and leadership in the global industrial field. As QIBR continues its journey of growth and advancement, all buyers can expect excellent product longevity, reliability and performance with every piece of QIBR marked bearing.

The first precision ball bearings were successfully produced in our newly established workshop. This achievement marks an important step in our journey towards providing best-in-class products to our valued customers.

We are able to manufacture bearings according to ISO 9001. And we also produce 2 million pieces of precision ball bearings every year according to customers' drawings.

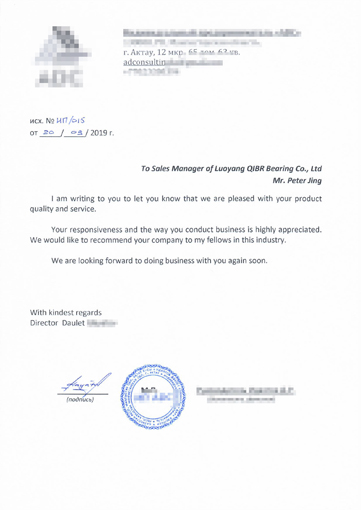

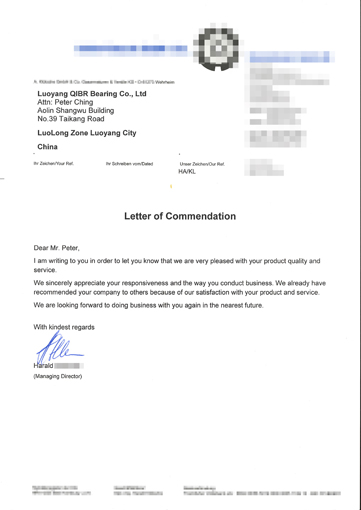

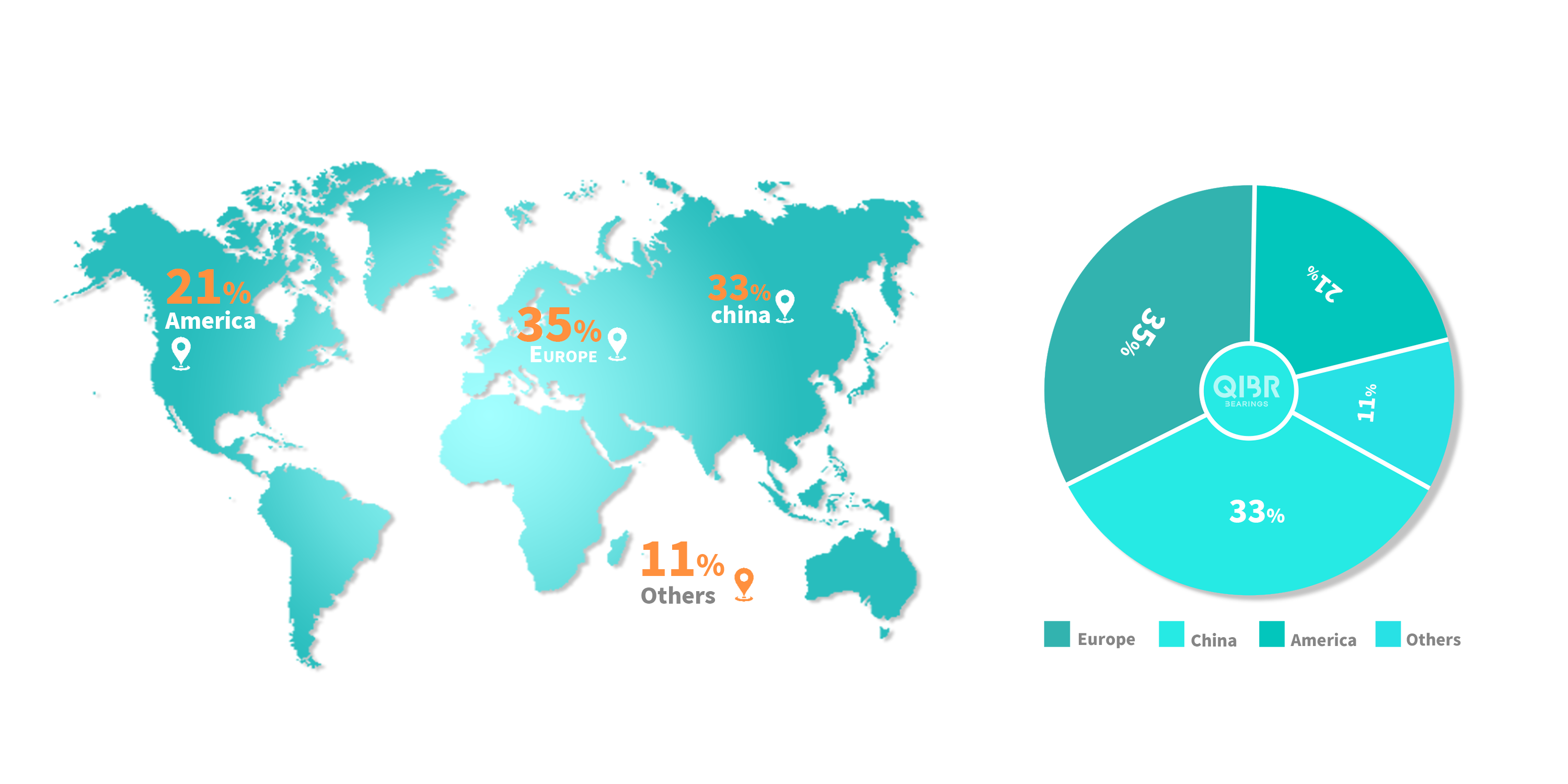

QIBR Bearings serves customers in more than 30 countries around the world. These partnerships form the cornerstone of our global business and inspire us to continuously improve the standards of product quality and customer service. We remain committed to further expanding our global footprint and entering new markets. With every satisfied customer, we lay the foundation for continued growth and prosperity for years to come.

QIBR Shandong Linqing branch factory was established, mainly responsible for the production of thin-wall bearings and the assembly of other bearings.

We implement 6S management and lean manufacturing system, and plan to invest in new work plant.

The construction of the second factory in Luoyang began. The new factory covers an area of 30,677 square meters. The Luoyang new factory obtained the ISO9001:2015 certificate.