Quality

Ensuring every product is designed, with materials and quality level that meets or exceeds every customer's requirements.

Pre-production Inspection

Pre-production inspection is crucial to reduce quality risks, QIBR conducts random sampling inspections of raw materials before the production stage to ensure that raw materials meet specific standards.

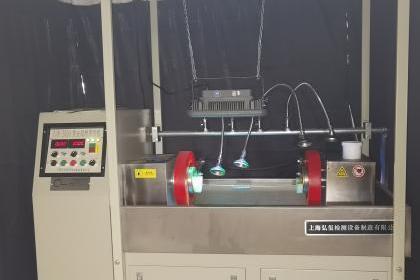

Bearing Magnetic Particle Detector

CJW-2000It is a non-destructive testing method. It can detect extremely fine defects on the surface and near-surface of components caused by casting, forging, welding, stretching, quenching, grinding, fatigue, as well as inclusion, etc.

Vickers hardness

HV-50To ensure hardness within the appropriate range and to meet usage requirements. Measuring the hardness through hardness testing instrument.

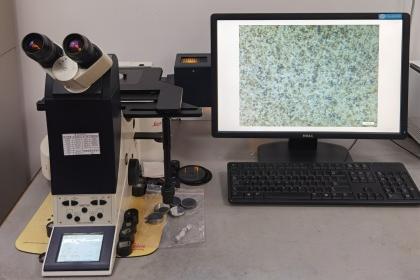

Metallographic Microscope

DMi5000The metallographic microscope can analyze the material composition and internal structure of bearings, used for quality control during the bearing manufacturing process, analyze issues such as fatigue cracks, deformation, stress concentration, etc., and perform failure analysis of bearings.

In-process Inspection

Conducting compliance inspections on the first product off the production line ensures that if any issues arise, the factory can take some corrective measures immediately to avoid delays.

“ In-process Inspection: Conducting compliance inspections on the first product off the production line ensures that if any issues arise, the factory can take some corrective measures immediately to avoid delays.”

Bearing Residual Magnetic Detector

Bearing residual magnetometer and digital bearing residual magnetism instrument is a special instrument for bearing residual magnetism inspection. It is mainly used for spot inspection of residual magnetism of finished bearings, also can be used for sampling parts of the production line.

Vibration test

Used to detect the vibration level of the bearing during operation. Abnormal vibrations may be an indicator of bearing failure.

Profile Gauge

Assessing the micro-features on the surface of bearings, primarily used for measuring groove R values and Pt values on deep groove ball bearings and ball screw channels.

Coordinate Measuring Machine

Used to measure the size, shape and position of bearings. It can measure points, lines, and surfaces, and provide high-precision three-dimensional coordinate information.