Luoyang QIBR Bearing company was established in 2002, which is a high-quality bearing manufacturing company that specializes in production, design, research and development. With over 22 years of experience in power transmission, the company possesses advanced technological research and development capabilities. Its product range mainly consists of three types: high-speed precision angular contact ball bearings, thin section ball bearings, and high-precision, low-noise deep groove ball bearings. These products are widely used in various industries including automotive transmission systems, high-precision CNC machinery, Ultra-high speed motorized spindle device, wind and solar energy equipment, and diversified industrial sectors.

QIBR has established a municipal-level technology center and a state-level specialized bearing engineering technology research and development center to develop new products and enhance the functionality of bearing designs. The company owns three major experimental centers for material analysis, physico-chemical experiments, and precision measurement. It strictly adheres to the German TUV ISO9001:2015 and ISO14001:2015 management systems, employs online inspection and SPC process control systems to achieve full monitoring and tracking of product processes. Our core technologies and key products ensure its leading position in the international market.

QIBR is dedicated to producing high-precision, high-quality bearings and has gradually become one of the comprehensive manufacturers in the China bearing industry, integrating production, sales, warehousing, and distribution.

1. Why Choose QIBR Bearings?

- QIBR owns a professional team of technical engineers who provide a range of services including technical consultation, fault detection, and fault analysis.

- OEM/ODM is available: We offer extensive OEM/ODM service, catering to the customization needs of world’s top enterprises. Our professional OEM/ODM team has rich experience in product design, production, and delivery.

Learn more about OEM-related case

- A leading Chinese quadcopter drone manufacturer

- A prominent Chinese new energy vehicle manufacturer

- A globally recognized elevator manufacturer

- A world-renowned machine tool manufacturer

- A globally acclaimed robotic arm manufacturer.

- Warranty: QIBR offers a one-year warranty period from the date of delivery.

- With over 20 years of experience in bearing manufacturing and sales, QIBR has established two wholly-owned factories in China equipped with over 20 production lines. This ensures quality assurance and high levels of reliability.

- From conception to bearing design solutions, QIBR assists customers every step of the way.

2. QIBR Can Undertake Research & Development Projects in:

- Super-high-speed ball bearings (inner diameter above 6mm, outer diameter below 360mm, speed factor less than 4 million)

- High temperature & high-speed bearing (Inner diameter above 6mm, outer diameter below 200mm, operating temperature below 470°C, speed factor less than 4 million)

- Thin section ball bearings: (width above 3.969mm, outer diameter below 300mm)

- Special bearings with functional coatings

- Special bearings for difficult-to-process materials

Company

Profile

QIBR is committed to

establishing long-term cooperative relationships with customers, providing innovative products, and cultivating professional employees.

Liu Bing

We established a company for the sales of bearings in Luoyang, Luoyang is one of the famous heavy industry cities in China, It has a civilization history of more than 5,000 years. There are 3 world cultural heritage sites located here, including the Longmen Grottoes, the Grand Canal of China (Huiluocang and Hanjiacang ruins), the Silk Road (the ancient cities of the Han and Wei dynasties, the Dingding Gate of Luoyang City in the Sui and Tang Dynasties, and the Hanhangu Pass ruins in Xin'an).

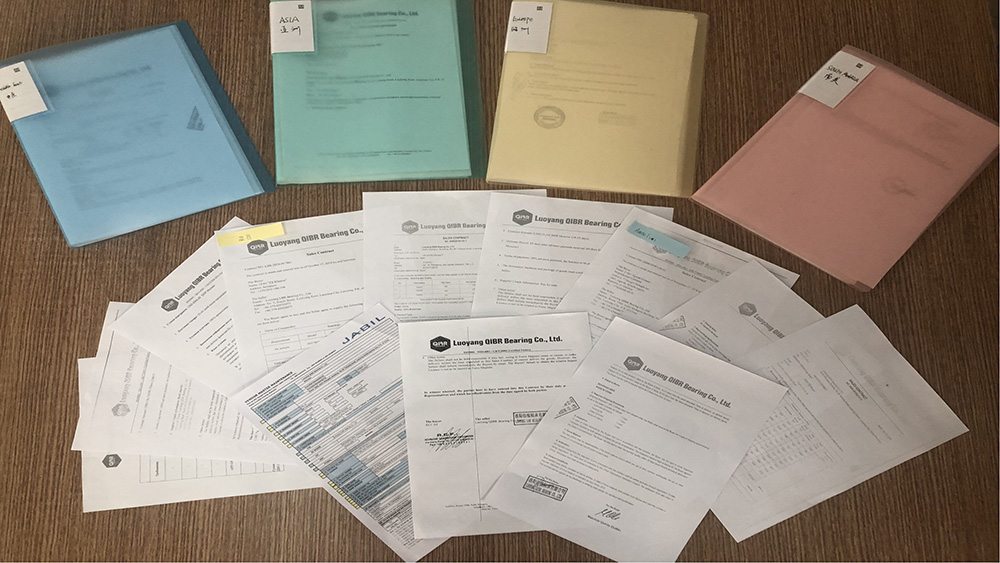

To ensure quality control of the products sold, we purchased a number of measuring instruments and created a laboratory for 100% quality control of bearings sold by our company.

Due to the opening of the direction of auto delivery, our company's turnover increased by 200%, both in the domestic market and in external markets (Russia, Central Asia)

A new QIBR plant started to be built, spanning an impressive area of 7700 square meters. This endeavor marks a pivotal moment in the company's expansion strategy and signifies a commitment to enhancing production capacity and bolstering regional economic growth. Upon completion, the plant is projected to significantly augment QIBR's production capacity, enabling the company to meet the evolving needs of its global clientele while maintaining stringent quality standards.

We're thrilled to announce significant progress in the expansion of QIBR's manufacturing capabilities. Construction has commenced on our new plant buildings, marking a pivotal step forward in our growth journey. Additionally, we're delighted to share that we've finalized agreements with leading European manufacturers for the supply of state-of-the-art equipment.

Commissioning of the production workshop. The commissioning of the production workshop heralds a new era of excellence and innovation for QIBR, propelling the company towards greater heights of success and leadership in the global industrial landscape. As QIBR continues its journey of growth and advancement, stakeholders can anticipate unparalleled quality, reliability, and performance in every product bearing the QIBR insignia.

The successful production of our first pilot batch of ball bearings in our newly established workshop. This accomplishment marks a significant step forward in our journey towards delivering top-notch products to our valued customers.

Introduced automatic production lines for production of roller bearings (with iron, conical cylindrical). Sign contracts for delivering of ball bearings with companies such as BELAZ. Test roller bearings in China National Quality Supervision and Testing Center for Bearings laboratory.

We are able to make bearings according to GOST520-2011, ISO 9001. And also according to customer's drawings, produce 1million bearings per year??? We did it!!!

Purchase of two advanced automatic production lines dedicated to the production and assembly of bearings. This strategic investment represents a significant leap forward in our commitment to innovation and efficiency. With the integration of these cutting-edge production lines into our operations, we're proud to announce a remarkable 60% increase in our output capacity. This substantial surge in production capability allows us to meet growing demand from our customers while maintaining the highest standards of quality and reliability.

The successful acquisition and commissioning of an automatic heat treatment production line. This cutting-edge addition represents a major milestone in our commitment to innovation, efficiency, and product quality. At QIBR, quality is our top priority. The acquisition of this advanced production line underscores our unwavering commitment to delivering bearings of exceptional quality, reliability, and performance. By investing in the latest technology, we reinforce our dedication to meeting and exceeding the expectations of our customers.

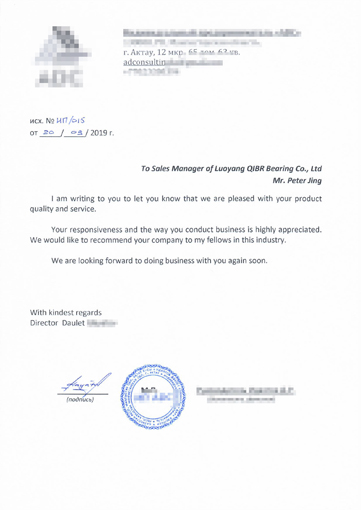

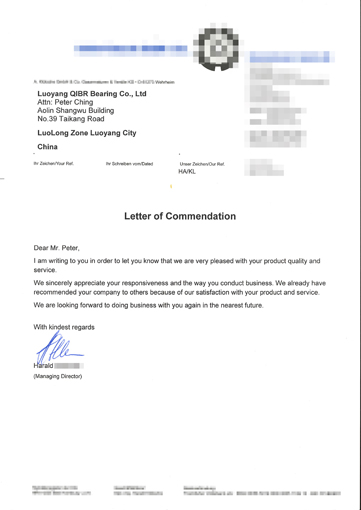

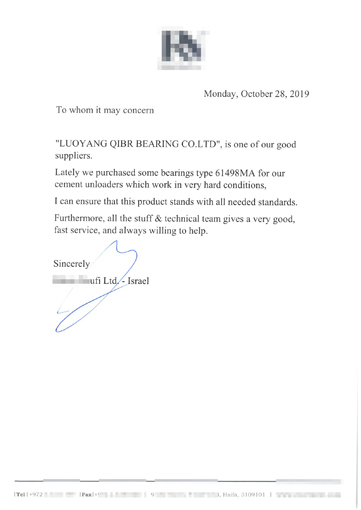

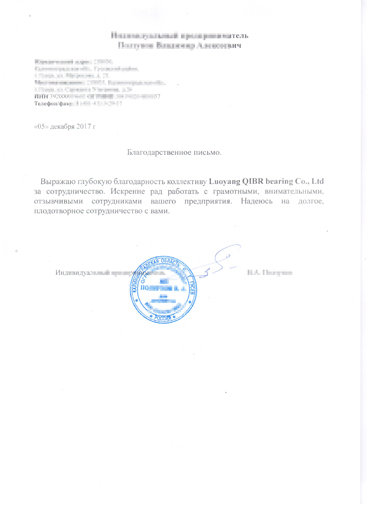

We're thrilled to announce that QIBR's dedication to excellence has been recognized far and wide, with customers in over 30 countries expressing their appreciation for the quality of our products. From Russia to Iran, Turkey to Spain, and beyond, our bearings have made a lasting impression on customers across the globe. The relationships we've cultivated with customers around the world go beyond mere transactions; they're partnerships built on trust, reliability, and mutual success. These partnerships form the cornerstone of our global presence and inspire us to continually raise the bar in product quality and customer service. As we celebrate our success in over 30 countries, we remain committed to further expanding our global footprint and reaching new markets. With each satisfied customer, we lay the foundation for continued growth and prosperity for years to come.

Our team has been steadily growing, our business expanding, and our client base continuously increasing. We've come to realize that our current office space is no longer sufficient to meet our needs. Therefore, in 2023, we decided to purchase a new 1000m2 office to support our current development and lay a solid foundation for our future growth.